News

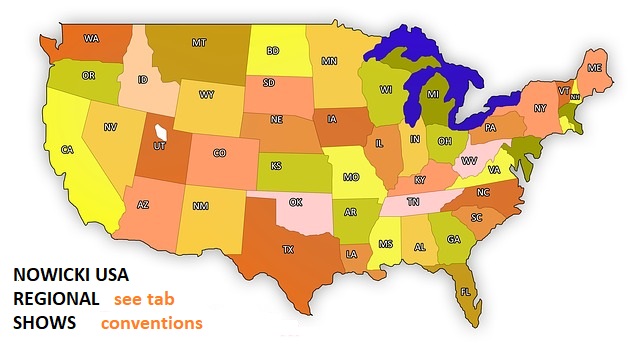

EPS will be exhibiting at upcoming shows around the country this year. In January we will be at IPPE and invite you to stop by our booth. IPPE January 25-27 2022 (Atlanta, Georgia) Booth # C12765 At the IPPE show we will feature Nowicki defrost tumbler systems, CelsiusFOOD teflon belt…

EPS will be exhibiting at upcoming shows around the country this year. In November we will be at Process Expo and invite you to stop by our booth. Process Expo November 2-5 (Chicago, IL) Booth # 2067 At the Process Expo show we will feature Nowicki defrost tumbler systems,…

Brine Injectors

MHM BRINE INJECTORS

Designed for brine injection of bone or boneless meat, meat products, whole poultry and poultry parts, fish and fish fillets.

Construction advantages:

- complete stainless steel construction

- option of high and low injections

- system of multifunctional injection heads (1-, 2-, 3- and 4-needle)

- quick and easy change of injection head with needles

- injection head stroke of 8” as a standard (4” and 10” are available as an option)

- two injection head speeds in a standard version

- smooth speed control (optional)

- simple and efficient power transmission system

- easy to read and operate control panel with intuitive touch screen

- plastic conveyer easy to disassemble and clean

- different conveyor speed controls

- highly efficient stainless steel centrifugal pump

- smooth brine pressure control up to 3 bar (4 bar as an option)

- stainless steel brine tank

- functions of brine mixing and brine pumping out from the tank

- closed brine circulation system

- helical pump for heavy brine (optional)

- easy to clean multistage brine filtration system

- option of brine cooling by a rotary filter (option for MHM-68/204, MHM-136/408)

| Type of injector |

MHM-21/84

|

MHM-39/156

|

MHM-68/204

|

MHM-136/408 * | |

| Number of sockets | pcs. | 21 | 39 | 68 | 136 |

| Max. number of needles | pcs. | up to 84 | up to 156 | up to 204 | up to 408 |

| Dimensions: L = Length | mm | 1510 | 1770 | 1740 | 2120 |

| B =Width | mm | 760 | 840 | 960 | 960 |

| H = Height | mm | 1850 | 2000 | 1950 | 1950 |

| Weight | kg | 330 | 430 | 490 | 680 |