News

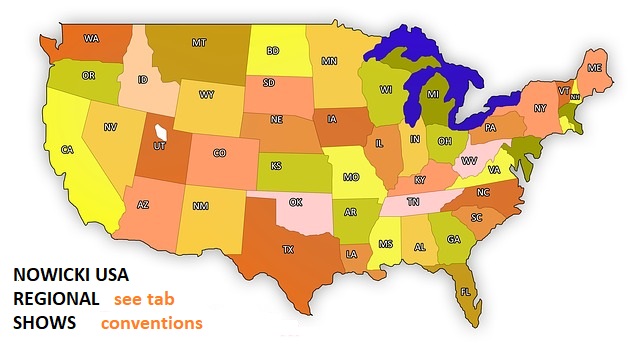

EPS will be exhibiting at upcoming shows around the country this year. In January we will be at IPPE and invite you to stop by our booth. IPPE January 25-27 2022 (Atlanta, Georgia) Booth # C12765 At the IPPE show we will feature Nowicki defrost tumbler systems, CelsiusFOOD teflon belt…

EPS will be exhibiting at upcoming shows around the country this year. In November we will be at Process Expo and invite you to stop by our booth. Process Expo November 2-5 (Chicago, IL) Booth # 2067 At the Process Expo show we will feature Nowicki defrost tumbler systems,…

Container Washers

Designed to wash a variety of plastic containers, covers of containers, euro-pallets* and buggies*, giving optimal washing effects.

The MP-300, MPU-600 Container Washers are available in a modular version (with option of extension of the initial washing module and/or the air blow-off module).

* MPU-600

Construction advantages:

- water heating systems: electric, steam, electric-steam, gas, oil and hot water

- guiding mechanism for washed containers

- mechanical conveyor for containers transport with speed regulation (chain conveyor)

- touch screen control panel

- closed water circulation system

- stainless steel centrifugal pump

- high efficiency – up to 600 containers per hour (for MPU-600)

- regulation and distribution of rinsing water in terms of: intensity of rinsing, refreshing of tank water, overflow

- system allows water savings in the washer in case of temporary lack of a container in the tunnel

- chemical dosing

- optional devices available, i.e., pre-wash and air blow-off modules

- guards protection against accidental opening

Accessories:

ROTARY FILTER

- self-cleaning rotating filter with impurities separator

- possibility of setting on the left or right side of machine

Washing Nozzles

- nozzles mounted in the collectors pipes for easy disassembly and cleaning of the entire collectors

- number of nozzles depends on shape of the container

- use of nozzles with different cross-sections for inside of the container and external walls, allowing the stream of water with different impact to be directed to a specific location of the container

- option of using acid-resistant nozzles – without changing the angle of water (this eliminates the possibility of incorrect assembly of the nozzle) or plastic nozzles that allow you to change the angle; easy to disassemble and clean

Touch Screen Control Panel

Control of the following washer processes:

- pumps’ switching on and off with operation signaling

- switching on and off conveyor with a smooth speed adjustment and operation signaling

- water temperature control system and temperature hysteresis together with an easy to read display of set and current parameters

- automatic system of water level control

- switching on detergent pump with signaling of detergent shortage

- counting of containers (optional)

- counting of work time (optional)

- emergency stop, safety switches

- easy to read and operate

- option of choosing an operation language

- auto-diagnostics of failures, indicated in the form of messages

| Type |

MPP-150

|

MP-300

|

MP-400

|

MPU-600 | |

| Efficiency | containers/h | do 150 | do 300 | do 400 | do 600 |

| Dimensions:

H=Height |

mm |

1820 |

2004 |

2010 | 1985 |

| B=width | mm | 1057 | 1210 | 1390 | 1510 |

| L+ L1=length | mm | 2629 | 3630 | 3850 | 3800 |

| Weight | kg | 460 | 700 | 790 | 850 |