News

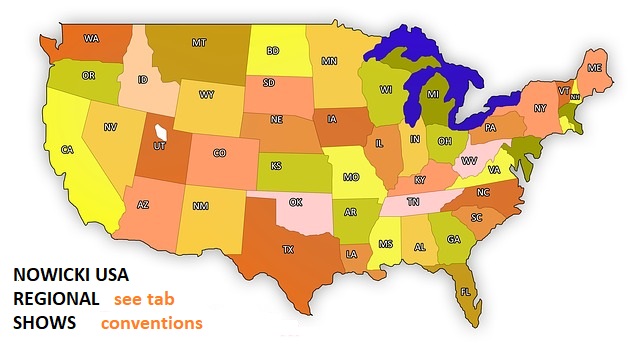

EPS will be exhibiting at upcoming shows around the country this year. In January we will be at IPPE and invite you to stop by our booth. IPPE January 25-27 2022 (Atlanta, Georgia) Booth # C12765 At the IPPE show we will feature Nowicki defrost tumbler systems, CelsiusFOOD teflon belt…

EPS will be exhibiting at upcoming shows around the country this year. In November we will be at Process Expo and invite you to stop by our booth. Process Expo November 2-5 (Chicago, IL) Booth # 2067 At the Process Expo show we will feature Nowicki defrost tumbler systems,…

Dripping Tunnel

Our dripping tunnel was created to carry out two processes after injection. One is to separate the excess brine from the injected elements; the second is to seal visible needle holes (in the case of injection of poultry carcasses or poultry portions with skin). Injected product is turned while moving forward through the dripping tunnel, the excess brine is separated and at the same time, the visible needle holes on the skin are concealed. This dripping tunnel can also be used to separate free brine, continuously, from the injected muscles for production of smoked products.

| Type | TO-1 | TO-2 | |

| Length of drum | mm | 3500 | 2500 |

| Drum revolutions | rpm | 0÷25 | 0÷25 |

| Dimensions

L=length |

mm |

4000 | 3370 |

| B=width | mm | 1270 | 1270 |

| H=height | mm | 2080 ÷ 2340 | 1810 ÷ 2000 |

| weigth | kg | 1130 | 1165 |