News

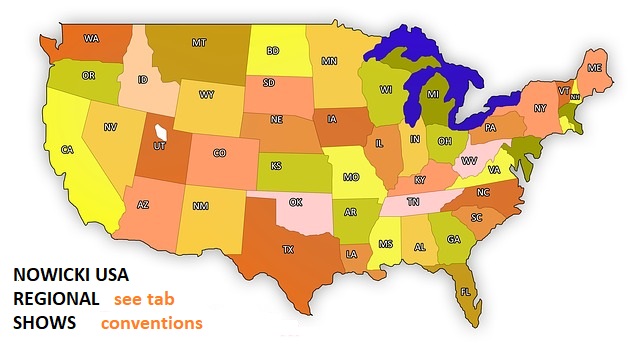

EPS will be exhibiting at upcoming shows around the country this year. In January we will be at IPPE and invite you to stop by our booth. IPPE January 25-27 2022 (Atlanta, Georgia) Booth # C12765 At the IPPE show we will feature Nowicki defrost tumbler systems, CelsiusFOOD teflon belt…

EPS will be exhibiting at upcoming shows around the country this year. In November we will be at Process Expo and invite you to stop by our booth. Process Expo November 2-5 (Chicago, IL) Booth # 2067 At the Process Expo show we will feature Nowicki defrost tumbler systems,…

Dual Brine Preparation System

Designed for brine preparation with large quantities of dry ingredients. The system allows for quick and effective achievement of consistent brine used in food processing. Two tanks (preparing and storing), two efficient pumps, a computer control system and cooling system, all allow for effective injection and massaging processes, resulting in improved quality of the final product.

Construction advantages:

Open construction of the dual brine preparation system meets the highest hygienic requirements and enables customization to individual customer needs by:

- changing overall dimensions of entire unit

- changing volume and dimensions of brine tanks

- installation of brine cooling system with an independent cooling unit or option of connecting it to customer’s internal cooling system

- full automation and control of the process by:

– automatic valve control

– electric control of water quantity

– control of pumped out ready solution quantity for further processing

– temperature control - option of using a vertical lifter

- optional system operation with high viscosity brine by:

– stronger and more effective high share pumps

– vibrator mounted on the hopper - option of using mechanical agitators

| Type | ZMS-750 | ZMS-1000 | ZMS-1500 | ZMS-2000 | |

| Tank capacity | dm3 | 2×750 | 2×1000 | 2×1500 | 2×2000 |

| Dimensions: L=length | mm | 2595 | 3300 | 3850 | 4070 |

| B=width | mm | 1642 | 2100 | 2300 | 2280 |

| H=height | mm | 1977 | 2450 | 2450 | 2500 |

| Weight | kg | 900 | 1100 | 1200 | 1650 |