News

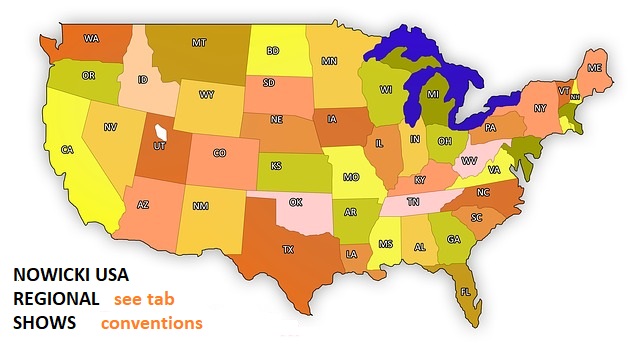

EPS will be exhibiting at upcoming shows around the country this year. In January we will be at IPPE and invite you to stop by our booth. IPPE January 25-27 2022 (Atlanta, Georgia) Booth # C12765 At the IPPE show we will feature Nowicki defrost tumbler systems, CelsiusFOOD teflon belt…

EPS will be exhibiting at upcoming shows around the country this year. In November we will be at Process Expo and invite you to stop by our booth. Process Expo November 2-5 (Chicago, IL) Booth # 2067 At the Process Expo show we will feature Nowicki defrost tumbler systems,…

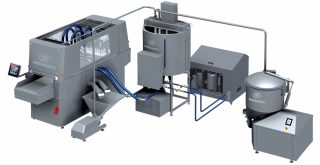

Meat in Meat Injection Line

A new quality of injection

The MM line is designed for injecting meat emulsion into the muscles and meat elements. It is an integrated, fully automated system, from preparation of meat emulsion, storage, injection into the muscles, grinding the return emulsion, and its return to the injection system. The meat-with-meat line provides opportunities to improve the quality of the manufactured products at the desired level of injection, increasing profitability of production and increasing the meat content of the finished product while maintaining high quality standards.

The MM line consists of the following units:

- emulsion preparation unit

- tank for storage and cooling emulsion with an independent refrigeration unit

- injector

- emulsifier for grinding the return brine

Benefits

The SAS system

- the SAS system

- easy and quick replacement of injecting heads

- injection value from 5% to 150%

- high production performance

- high repeatability of injection

- unique washing system

- improved meat content of the product

- increased profitability

- improved product quality

- use of cut meats

- compact line design