News

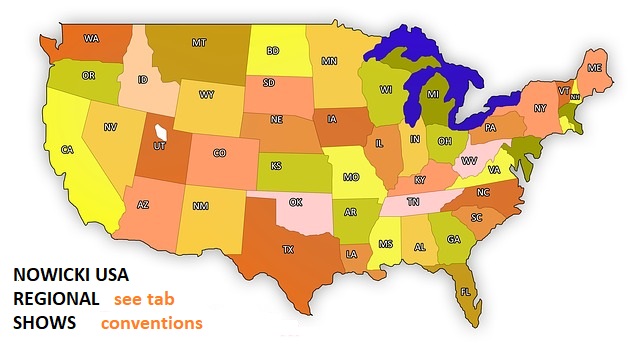

EPS will be exhibiting at upcoming shows around the country this year. In January we will be at IPPE and invite you to stop by our booth. IPPE January 25-27 2022 (Atlanta, Georgia) Booth # C12765 At the IPPE show we will feature Nowicki defrost tumbler systems, CelsiusFOOD teflon belt…

EPS will be exhibiting at upcoming shows around the country this year. In November we will be at Process Expo and invite you to stop by our booth. Process Expo November 2-5 (Chicago, IL) Booth # 2067 At the Process Expo show we will feature Nowicki defrost tumbler systems,…

Roller Tenderizer

DESIGNED FOR SOFTENING MEAT MUSCLES IN ORDER TO INCREASE ABSORPTION OF BRINE AND TENDERNESS OF PRODUCT.

Designed for notching both sides of meat muscles in order to increase absorption of brine. Perfect in cutting hard tissues and muscle tendons which increase the absorption surface resulting in a tenderized meat products.

Construction advantages:

- stainless steel execution

- multi–roller system based on two tenderizing shafts

- easy shaft assembly and disassembly for maintenance and cleaning process

- upper shaft’s smooth adjustment of pressure allows for optimal working conditions for different meat elements

- option of using different shaft’s shapes, depending on type of operations

- auto adjustment of thickness of tenderized meat from a control panel

- two synchronized transport tables – loading and discharge

| Type | T-600S | |

| Type | roller | |

| Number ofcutting chafts | pcs. | 2 |

| Number of knives on a shaft | pcs. | 69 (101 optional) |

| Tenderizing width | mm | 600 |

| Dimensions: L=length | mm | 1900 |

| B=width | mm | 1268 |

| H=height | mm | 1522 |

| Weight | kg | 900 |