News

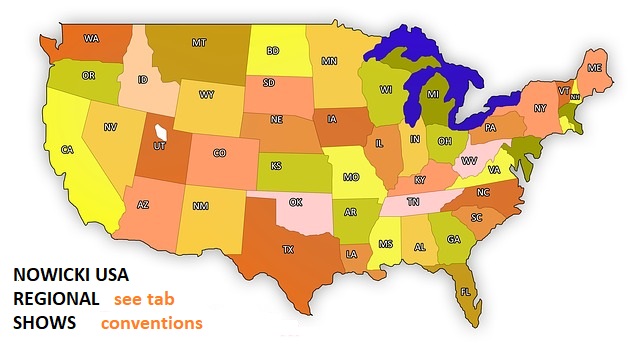

EPS will be exhibiting at upcoming shows around the country this year. In January we will be at IPPE and invite you to stop by our booth. IPPE January 25-27 2022 (Atlanta, Georgia) Booth # C12765 At the IPPE show we will feature Nowicki defrost tumbler systems, CelsiusFOOD teflon belt…

EPS will be exhibiting at upcoming shows around the country this year. In November we will be at Process Expo and invite you to stop by our booth. Process Expo November 2-5 (Chicago, IL) Booth # 2067 At the Process Expo show we will feature Nowicki defrost tumbler systems,…

TAURUS Automatic Angle Grinders

Designed for grinding fresh and frozen meat down to -4 o F to required granulation, and other technological operations depending on used equipment.

The grinders have a wide range of applications in the industry:

- Meat processing

- Fish and seafood processing

- Pet-food, convenience food

- Fruit and vegetable

- Confectionery

Construction advantages:

- high quality stainless steel execution

- high ground product quality

- execution of pressing chamber and pressing worm in highly resistant stainless steel

- two compatible drives of a feeding worm and a pressing worm ensure optimal dosed material adjustment amount

- smooth feeding worm regulation (optional)

- cutting system with quality cutting devices

- automatic adjustment of material feeding to set pressing worm load

- pressing worm equipped with automatic pushing out system (option W-160, W-200)

- grinders equipped with peripheral device for separation of tendons and membranes (option) and separator of poultry bones (option)

- safety systems for optimum working safety

- microprocessor controller responsible for control of all work parameters

- pressing worm made of single metal element without welding process

- grinding system for frozen meat blocks (-4 o F) (optional)

- special execution of grinders for frozen fish blocks

- adjusted for various types of loading

- easy to clean

| Types | W-130 | W-160 | W-200 | |

| Diameter of throat | mm | 130 | 160 | 200 |

| Capacity of hopper | dm3 | 360 (110**) | 360 | 450 |

| Dimensions: L=length/ length with loader |

mm | 1460/2310* (1690)** | 1810/2650* | 2260/3110* |

| B=width/width with loader | mm | 1510/1750* (1540)** | 1780/1940* | 1830/1990* |

| H=height/height with loader | mm | 1650/3000* (1500-2130)** | 1900/3250* | 1950/3280* |

| Weight/weight with loader | kg | 1255/1500* (1225)** | 2100/2300* | 2700/3100* |

* dimensions with vertical loader

** technical data of the W-130 in the version for manual loading