News

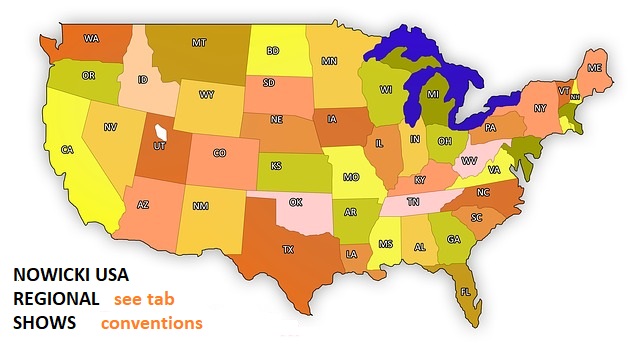

EPS will be exhibiting at upcoming shows around the country this year. In January we will be at IPPE and invite you to stop by our booth. IPPE January 25-27 2022 (Atlanta, Georgia) Booth # C12765 At the IPPE show we will feature Nowicki defrost tumbler systems, CelsiusFOOD teflon belt…

EPS will be exhibiting at upcoming shows around the country this year. In November we will be at Process Expo and invite you to stop by our booth. Process Expo November 2-5 (Chicago, IL) Booth # 2067 At the Process Expo show we will feature Nowicki defrost tumbler systems,…

Universal Modular Container Washers

MODULAR TUNNEL CONSTRUCTION ALLOWS FOR UNIVERSAL CONNECTION OF EACH MODULE USED IN THE CONTAINER WASHING PROCESS

- Touch screen control panel

- Rotary filter (optional)

- self-cleaning rotating filter with impurities separator

- option of setting on the left or right side of machine

- High pressure nozzles with adjustable angle for optimum results

- Capable of operating with automatic container storage systems

- High efficiency

- Limit water consumption in the washer (directing recovered water to a tank)

- Regulation of air stream intensity (fast change of nozzle distances from container surface)

Modular tunnel construction of the washers allows for universal connection of each module used in the container washing process.

INITIAL WASHING MODULE

The initial washing module is mechanically and electrically compatible with the main washing module.

Construction advantages:

- stainless steel construction

- increase of washing efficiency

AIR DRY MODULE

Designed to remove water from the surface of the containers and other packages after washing and disinfecting processes in washers. Compatible with other modules of the washing line. With proper configuration of blow-off modules, it’s possible to reduce water from the container up to 99% (depends on shape and technical condition of the container).

- high efficiency

- limit water consumption in the washer (directing recovered water to a tank)

- regulation of air stream intensity (fast change of nozzle distances from container surface)

Initial washing module (MW-300, MW-600) and Air dry module (SO-300, SO-600) – technical data

| Type |

MP-300 +

MW-300

|

MP-300 +

MW-300 +

MW-300

|

SO-300

|

MPU-600 +

MW-600 |

MPU-600 +

MW-600 + MW-600 |

SO-600

|

|

| Efficiency | containers/ h | 300 | 300 | up to 300 | 600 | 600 (900) | up to 600 |

| Dimensions H = Height |

mm | 2010 | 2010 | 1760 | 2240 (2640) | 2240 (2640) | min. 2145, max. 2640 |

| B = Width | mm | 1010 | 1010 | 1010 | 1370 | 1370 | 1370 |

| L = Length | mm | 5520 | 7440 | 2004 | 5550 (5880) | 7270 (7570) | 2080 |

| Weight | kg | 600+590 | 600+590+590 | 420 | 740+700 | 740+700+700 | 760 |