News

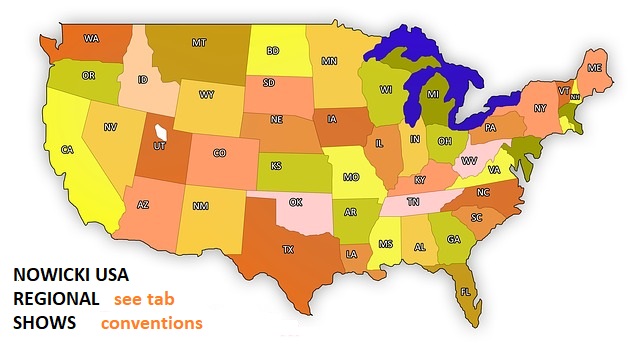

EPS will be exhibiting at upcoming shows around the country this year. In January we will be at IPPE and invite you to stop by our booth. IPPE January 25-27 2022 (Atlanta, Georgia) Booth # C12765 At the IPPE show we will feature Nowicki defrost tumbler systems, CelsiusFOOD teflon belt…

EPS will be exhibiting at upcoming shows around the country this year. In November we will be at Process Expo and invite you to stop by our booth. Process Expo November 2-5 (Chicago, IL) Booth # 2067 At the Process Expo show we will feature Nowicki defrost tumbler systems,…

Horizontal Vacuum Tumblers Type MA

Horizontal Vacuum Tumblers are intended for improving vividness, massaging and marinating a wide range of raw materials in a vacuum:

- red meat muscles and elements

- small meat pieces

- poultry body items and elements

- fish and seafood

Construction advantages:

WIDER POSSIBILITIES FOR CONTROLLING THE MASSAGING PROCESS PARAMETERS The specially designed drum construction and control of the parameters process results in higher quality of sausage products

Solid construction

- completely made of acid resistant steel

- polished drum durability inside and outside

- diagonal blades system

Process automation thanks to the advanced control system

- full control of all massaging process parameters

- all massaging processes are programmed and controlled by an intuitive touch panel

- diagnostic system via the Internet

Vacuum system

- BUSCH vacuum pumps as standard

- multistage vacuum pump protection system

Loading systems

- option of working with a hydraulic or vacuum loading system

- option of using one loading system for many tumblers

The highest quality of products

- control of process parameters results in high repeatability of products

- maintaining technological parameters because of specially designed drum construction and working in a vacuum environment

ACCESSORIES:

Advanced control system

- full control of all parameters of the massaging process

- all the massaging processes are programmed and controlled by means of an intuitive touch panel

- SCADA monitoring and recording system for work parameters

- diagnostic system via the Internet

- RFID control and identification system

Vacuum system

- BUSCH vacuum pumps as standard

- vacuum extraction through the shaft

- multistage vacuum pump protection system

- possibility to work with external pumps or central vacuum systems

Cleaning system

- system for cleaning the elements of the vacuum system

- inspection holes for easy hygiene maintenance

Automatic lids

- system of automatic covers for easy loading

| Types of Tumblers | MA-200 PS | MA- 500 PS | MA-1000 PS | MA-1500 PS | MA- 2000 PS | MA- 3600 PS | MA- 5400 PS | MA- 7200 PS | MA-10000 PS | |

| Drum capacity | dm3 | 200 | 500 | 1000 | 1500 | 2000 | 3600 | 5400 | 7200 | 10 000 |

| Maximum load | kg | ~120 | ~250 | ~500 | ~750 | ~1000 | ~1800 | ~2700 | ~3600 | ~5000 |

| Dimensions L=length | mm | 1700 | 2060 | 2580 | 2750 | 3150 | 3750 | 4100 | 4100 | 4900 |

| B=width | mm | 1180 | 1180 | 1260 | 1340 | 1340 | 1800 | 1960 | 2170 | 2240 |

| H=height | mm | 1540 | 1580 | 1570 | 1720 | 1720 | 2050 | 2250 | 2480 | 2480 |

| Weight PS/PSCH |

kg | 370 | 450 | 640 | 1050 | 1100 | 1700 | 2900 | 3200 | 3600 |