News

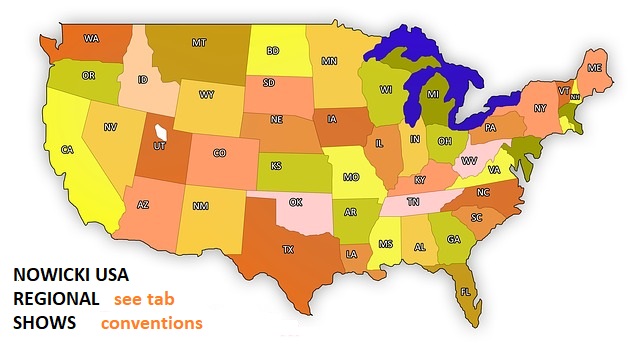

EPS will be exhibiting at upcoming shows around the country this year. In January we will be at IPPE and invite you to stop by our booth. IPPE January 25-27 2022 (Atlanta, Georgia) Booth # C12765 At the IPPE show we will feature Nowicki defrost tumbler systems, CelsiusFOOD teflon belt…

EPS will be exhibiting at upcoming shows around the country this year. In November we will be at Process Expo and invite you to stop by our booth. Process Expo November 2-5 (Chicago, IL) Booth # 2067 At the Process Expo show we will feature Nowicki defrost tumbler systems,…

Fish meat High speed rotation cutters TYPHOON

Designed to produce all kinds of meat stuffing with different degrees of crumbling and fat emulsions, also from raw skins.

Construction advantages *:

- stainless steel construction

- high quality and repeatability of stuffing production

- versatility: besides cutting, mixing of stuffing is also possible

- high-speed rotations of knife head (cutting rotations)

- microprocessor control system

- smooth control of cutting and mixing rotations

- possibility of programming up to 40 technological programs

- possibility of changing the language of operator panel

- stuffing unloader

- automatic water dosage system

- effective noise insulation cover

- head with cutting knives not requiring regulation of distance from bowl

- equal stuff crumbling in all the bowl’s volume caused by “cutting in the air”

- stuffing temperature control

- possibility to install a higher power motor for heavy stuffing production

- hydraulic loading and unloading system

- hydraulically operated front and back covers of the bowl

- monitoring system of the current machine operation, auto diagnostic and sound signaling system

- complete work safety system

- modern and ergonomic construction of the machine

- construction meets the highest hygiene requirements (flat surfaces inclined at an angle of 3 degrees)

- automatic central lubrication system

- product contact surfaces are polished

- emergency STOP for bowl drive and cutterhead drive

- removing of current disturbance through the use of variable frequency drive of cutter

|

Types of cutters |

KN-60

|

KN-125

|

KN-200

|

KN-330 | KN-550 | KN-750 | |

|

Bowl capacity |

dm3 | 60 | 125 | 200 | 330 | 550 | 750 |

|

Cutterhead speed |

|||||||

|

– working (adjusted) |

rpm | 200÷6000 | 200÷5000 | 200÷4800 | 200÷4500 | 200÷3800 | 200 ÷3800 |

|

– stuffing mixing (adjusted) |

rpm | (-200)÷(-400) | (-100)÷(-300) | (-100)÷(-300) | (-100)÷(-300) | (-100)÷(-300) | (-100)÷(-300) |

|

L (L1)= length (length with loader) |

mm | 1650 | 2530(2650) |

2820 |

3070 | 3680 | 3850 |

|

B (B1)= width (width with loader) |

mm | 1310 | 1500 (2000) | 2550 | 2530 | 2970 | 3080 |

|

H1= height with lowered cover |

mm | 1190 | 1850 |

2080 |

2160 | 2400 | 2650 |

|

H2= height with lifted cover |

mm | 1850 | 2300 | 2510 | 2770 | 3110 | 3230 |

|

Control box dimensions |

mm | 800x800x300 | 1000x1400x 400 |

1200×1800 x400 |

1200x1800x400 | 1200x2000x500 | 1000x2200x600 |

|

Weight with loader ( without loader) |

kg | (1350) | 2400 (2000) | 3600 | 4200 | 5650 | 7930 |