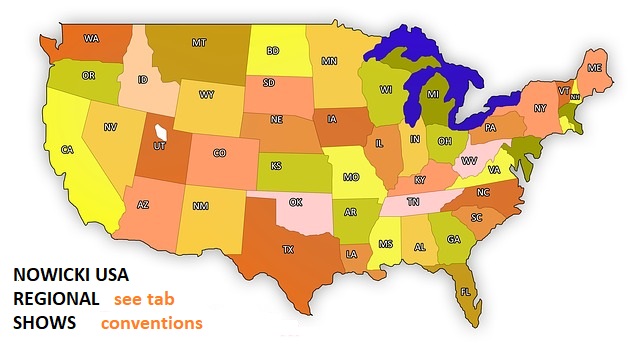

News

EPS will be exhibiting at upcoming shows around the country this year. In January we will be at IPPE and invite you to stop by our booth. IPPE January 25-27 2022 (Atlanta, Georgia) Booth # C12765 At the IPPE show we will feature Nowicki defrost tumbler systems, CelsiusFOOD teflon belt…

EPS will be exhibiting at upcoming shows around the country this year. In November we will be at Process Expo and invite you to stop by our booth. Process Expo November 2-5 (Chicago, IL) Booth # 2067 At the Process Expo show we will feature Nowicki defrost tumbler systems,…

Injection Line with Dripping Tunnel

Designed for industrial injection of poultry and red meat. Components of the injection line are: injector MH SAS, rotary filter FBN, dripping tunnel TO-1.

A variety of injectors with SAS SYSTEM – greater opportunities for control of injection process. SAS SYSTEM Meat Injectors are intended to implement the most complex injection processes covering a variety of raw materials, namely:

- muscles and elements of red meat with bone or boneless

- poultry carcasses and parts of white meat with bone or boneless

- red and white meat

- fish and fish fillets

SAS SYSTEM FEATURES:

- high repeatability of technological operations

- low injection rates up to 10%, as well as high injection rates over 100%

- latest, easy to assemble and disassemble injection head

- high production rates in lbs/h

- maximum injection head speed up to 60 cycles per minute

- injection of raw material of different thickness without extruding brine

- possibility of pre-programming moment of injection, i.e., determining the layer of raw material which will be injected

- transporter drive synchronized with injection head drive enables several combinations of injection patterns.

Modern filtration systems

Meat Injectors are equipped with multi-step filtration system:

- filter with replaceable cartridges with different graduation

- screen filter, consisting of the three grids with different graduation

- rotary filter with a slot drum for return brine cleaning

- sunken suction filter which minimizes the loss of brine

Dripping tunnel TO-1 is a device to carry out two processes after injection. One is to separate the excess brine from the injected elements, the second is to conceal visible needles holes (in case of injection of poultry carcasses or poultry elements with skin). By turning the injected elements in the dripping tunnel while moving them forward, the excess brine is separated and at the same time, the needle holes visible on the skin are concealed. In addition, the dripping tunnel can be used to separate free brine, continuously, from the injected muscles for production of smoked products.